millalyzer

Affordable Milling Process Analysis

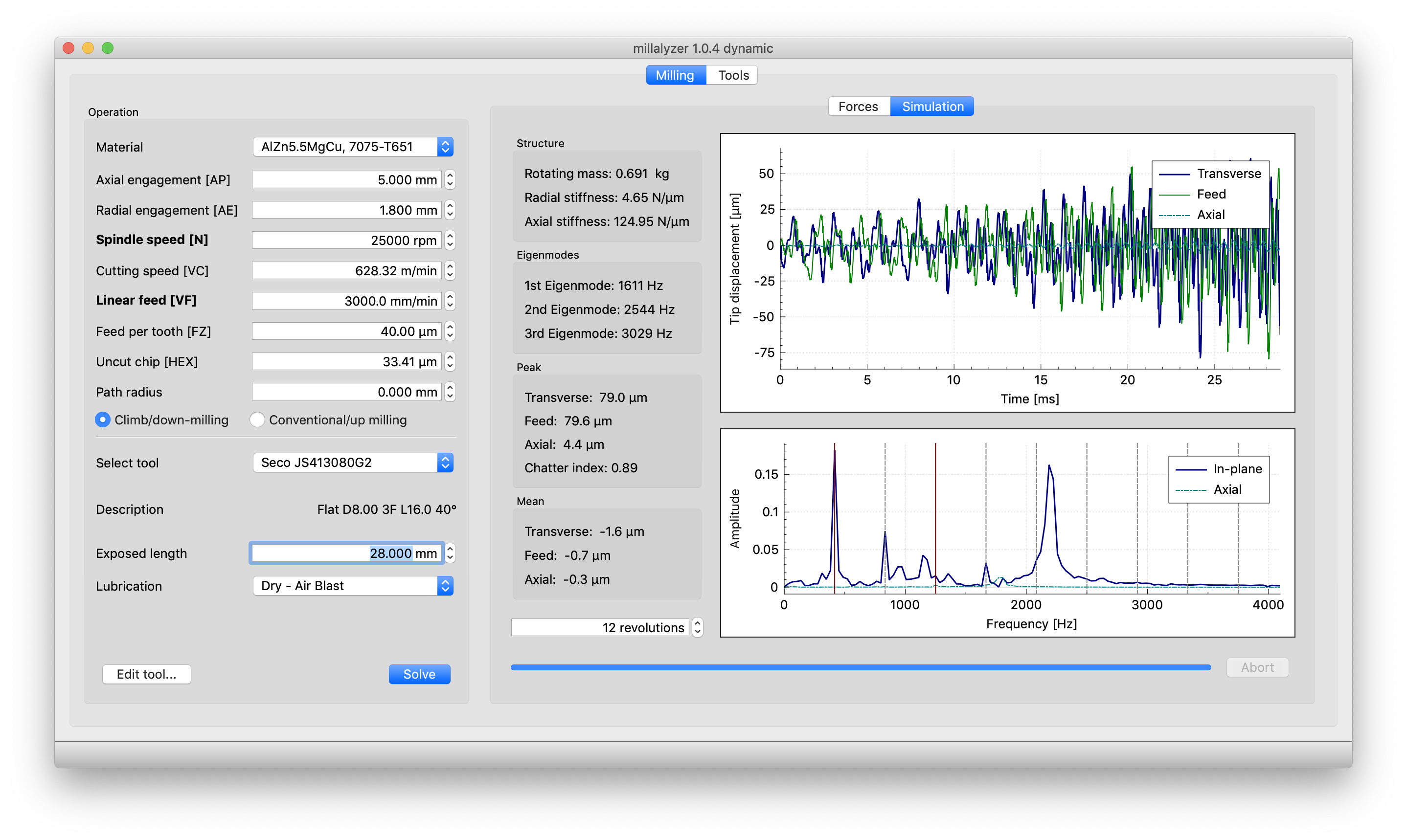

Millalyzer predicts milling forces and recommends machining parameters based on material properties and machine limitations.

Why Millalyzer?

Efficient force & chatter prediction using state-of-the-art numerical models, at an affordable price.

Any analysis completes in seconds, even process optimisation!

Well-founded numerical model, not just rules of thumb.

Carefully assembled flow-stress models means material behaviour is accounted for.

Reveal Process Forces

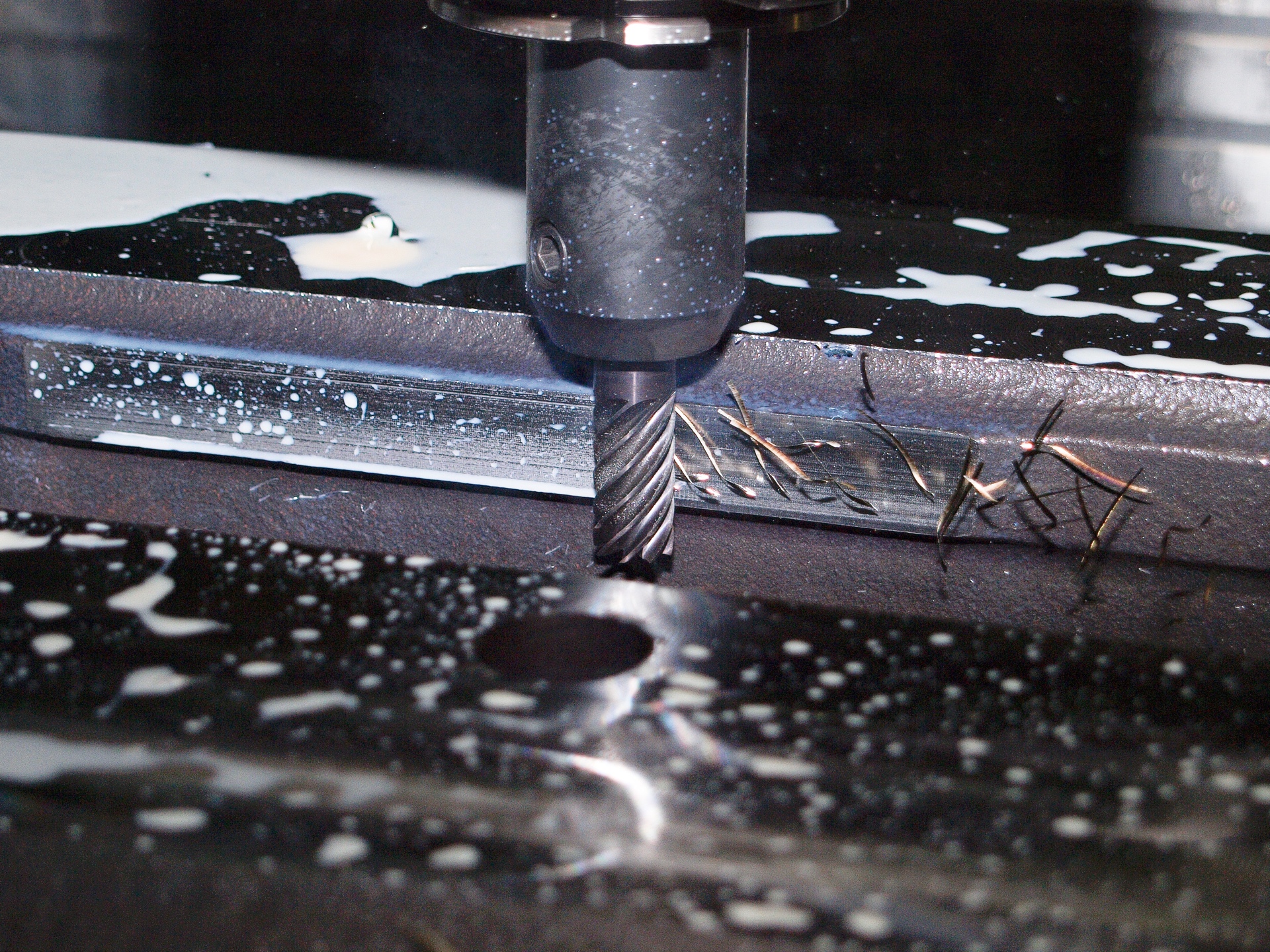

Millalyzer computes milling forces, tool tip deflection, spindle torque and power for peripheral (end-), facing and slot-milling operations. Run trade-off studies with different tools to see which fits your machine best. Evaluate the benefits of that expensive high-end endmill before buying it. Does a higher helix angle make sense for your needs? Better to increase width of cut or run more passes at higher feed? Millalyzer hands you the data, you decide.

Milling Tools

Millalyzer's tool definition interface is entirely open, the built-in tool editor lets you quickly define new endmills. Choose to define only the most important properties or enter all detail dimensions for accurate chatter analysis. Tool library files are plain-text files in YAML or CSV format, and can be saved and loaded freely.

Wondering whether those expensive high-end endmills with unequal helix angles and flute indexing make a difference? Millalyzer lets you try it out.

Boost Productivity

Let millalyzer find the maximum acceptable width or depth of cut, in seconds. Get the most out of your machine while staying within the constraints of your setup:

- Spindle torque and power limits

- Peak and mean forces by direction

- Tool stress limit - prevent tool failure

Millalyzer dynamic will also simulate structural vibrations and indicate the risk for chatter.

Materials Matter!

The built-in material database contains flow stress models and thermal data for a range of common aluminum and steel alloys. Models are not simple empirical relations, but based on research published by NPL, the Lawrence Livermore National Laboratory and many others. More materials will be added in the future and existing properties will be improved following the analysis of recently performed cutting tests.

Purchase

Millalyzer is available in two versions. Both versions can

- predict cutting forces reliably;

- find optimal cutter engagement values;

- define machine & spindle constraints;

- warn for premature tool failure.

while the dynamic version, additionally,

- simulates elastic tool motion;

- helps to avoid excessive chatter.

Newsletter

Subscribe to the low-traffic mailing list for news on millalyzer. Customers who opt-in to the product update newsletter on purchase will receive future bugfix updates free of charge.